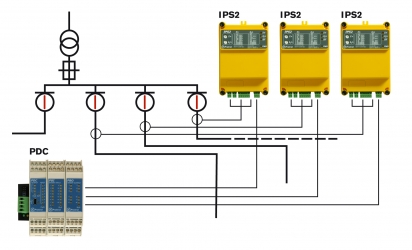

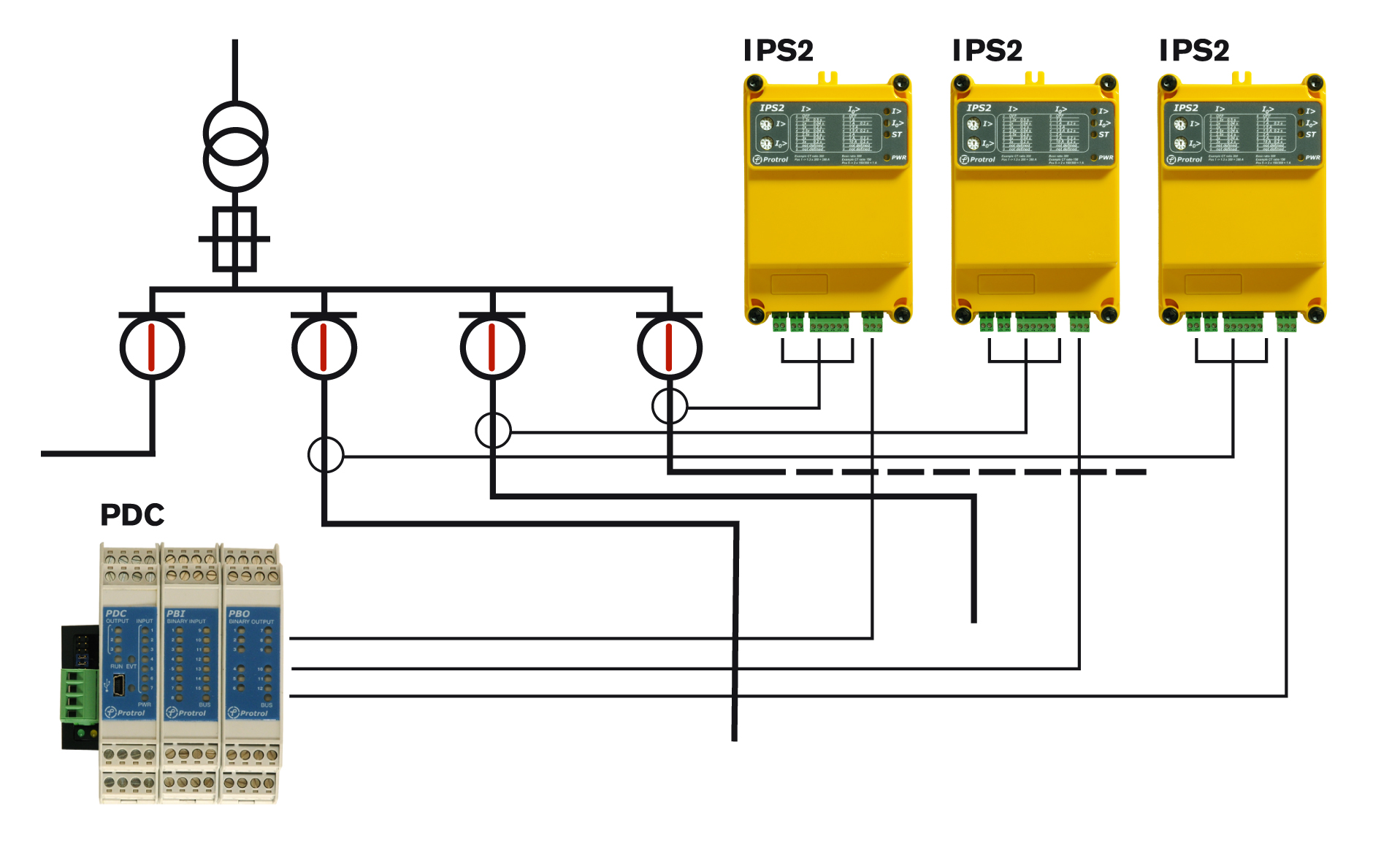

Q: What is unique with Protrol's earth fault detection algorithm?

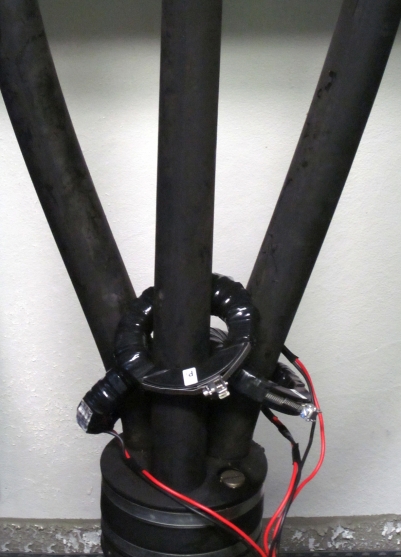

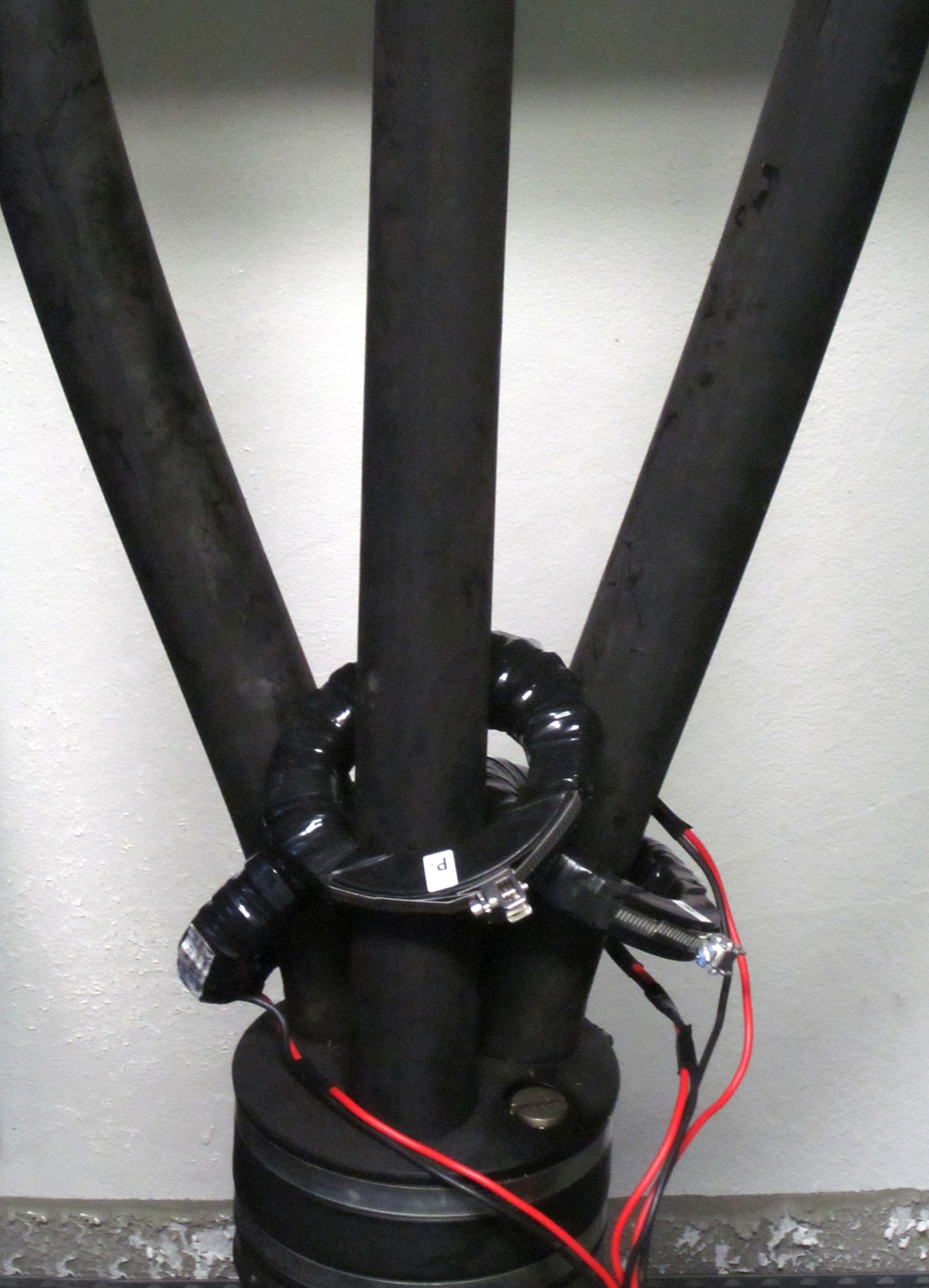

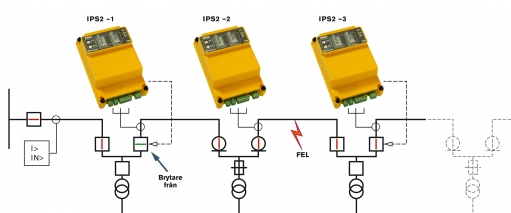

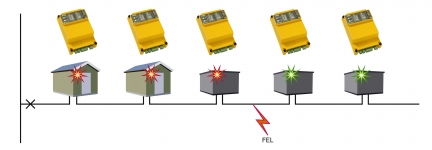

A: Protrol's algorithm determines the fault direction without any voltage reference by

analysing the three phase currents. These are measured by current transformers,

easy to mount.

In addtion, the detection algorithm has a high sensitivity and reliability for high

impedance and transient faults.